Compress packaging machine working video

About compress packaging machine

kodipak compress packaging machine is perfect equipment for packaging pillow, pillow core, plush toys, quilt, cushion, cloth, feather clothing, foam sponges, fluffy items, etc. compress packaging not only maintain the beauty of your product and moisture and avoid your product moistly, but also reduce the volume of your products. Compression packaging will help you to save on storage and transportation costs when compared to traditional packaging.

Compress packaging machine technical parameter

kodipak supply four different standard models KCP-600, KCP-800, KCP-1000, and KCP-1500 compress packaging machine to be suitable for packaging different size of the product. The machine is also customized by your product and request.

| Model | KCP-600 | KCP-800 | KCP-1000 | KCP-1500 |

|---|---|---|---|---|

| Sealing bar width | 8mm or 10mm | 8mm or 10mm | 8mm or 10mm | 8mm or 10mm |

| Sealing bar length | 600mm | 800mm | 1,000mm | 1,500mm |

| Table size | 650*650 mm | 850*850 mm | 1,150*1,150 mm | 1,650*1,650 mm |

| Control system | plc control system | plc control system | plc control system | plc control system |

| Stroke height | 300mm | 300mm | 500mm | 500mm |

| Machine material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Power | 1.0kw | 1.5kw | 2.0kw | 3.0kw |

| Working speed | 4-7 cycles per minute | 4-7 cycles per minute | 4-7 cycles per minute | 4-7 cycles per minute |

| Weight | 170kg | 220kg | 350kg | 490kg |

| Dimension | 750*750*900mm | 1,000*800*900mm | 1,390*1,100*900mm | 1,850*1,750*900mm |

Compress packaging machine features

- kodipak compress packaging machines are made of full 304 stainless steel and abrasive blasting treatment for extra strength. The double thickening stainless keep compress packaging better quality and over 10 years service life.

- Not only machine working chamber size is able to be customized according to customer request, But also the machine voltage also customized by customer request.

- The advance PLC control panel is easy to operate, with a memory function.

- compress packaging machine with an emergency stop button to ensure operator safety.

- Compress packaging machine used the best quality taiwan airtac pneumatic components.

Compress packaging machine working process

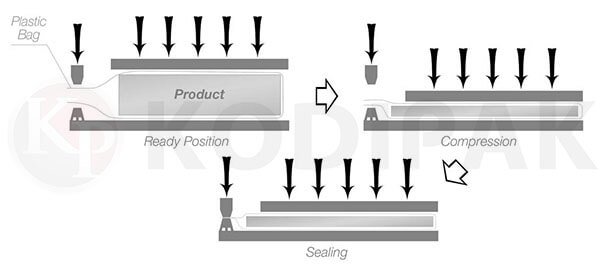

Kodipak compress packaging machine design to easy operation. Only need four steps, firstly, tum on the power switch and heating switch. secondly, place the product on the compressed area. And lean the opening on the aluminum or pack bag sealing bar and adjust the position of the package. Then Change the heating time and cooling time to the right parameter. With a normal bag (material: PE+PA) the heating time will vary from 0.6-1.2s and the cooling time will be 2-3s. Finally, Press the starting switch to start the sealing process. After the four processes, take out the compressed product and check the sealing. For a more detailed working process, please check the followed picture.

Compress packaging machine application

Kodipak compress packaging machine is widely used in the pillow, pillow core, plush toys, quilt, cushion, cloth, feather clothing, foam sponges, fluffy items, etc.

Compress packaging sample pictures