KDC-500 Double Chamber Vacuum Packing Machine Supplier

Machine working principle

A double chamber vacuum packing machine is a unique piece of equipment capable of preventing product damage. Two separate vacuum chambers, it can create equal air pressure between chambers without damaging the valuables or product. This feature allows for better efficiency and ultimately enables greater productivity.

Pack machine specification

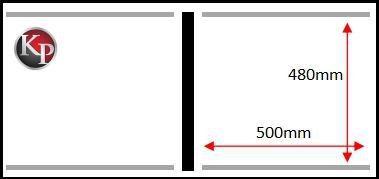

| Work chamber size | 500*480*120 mm |

|---|---|

| Chamber height | 120 mm |

| Work cycle | 2-4 cycles per minute |

| Power | 2.5 kw |

| Material | SUS304 food grade stainless steel |

| Control system | Timer control system |

| Weight | 250kg |

| Dimension | 1350*740*960mm |

Chamber size picture

Machine Features

- Commercial grade stainless steel swing-lid container with a handy flip-top.

- An industrial-strength, full gauge stainless steel container with a sturdy swing-lid that’s easy to open and close with one hand.

- Four high-quality, durable plastic wheels. All of the wheels lock for greater stability.

- Simple to operate, many program settings options

- Vacuum chamber fillers for different heights and closure options

Machine options

- PLC control system is able to choose.

- Vacuum pack machine work height is able to be customized by your request.

- Nitrogen gas flushing function system choice.

- Vacuum pump dust filter system

Vacuum Pack function

- Extend the shelf life of your product

- Keep food fresher by storing and transporting items in the right way

- Save money by keeping food fresh for longer

Vacuum Pack function

The machine is able to pack food and non-food. It’s able to fill many different types of packaging, including raw meats, fresh fruits and vegetables, tea bags, coffee, and chocolate. Vacuum packing non-food, hardware, medical instruments, medicine, pillow, etc.

Sample pack pictures