KDC-600 Double Chamber Vacuum Packing Machine Factory

Machine working principle

The double chamber vacuum packing machine is made up of two separate vacuum chambers. This feature allows packaging material to be placed in one chamber while the other vacuum chamber is being used. This improves the efficiency of both chambers and ultimately increases productivity.

Shrink pack machine specification

| Work chamber size | 600*580*120 mm |

|---|---|

| Chamber height | 120 mm |

| Work cycle | 2-4 cycles per minute |

| Power | 3.5 kw |

| Material | SUS304 food grade stainless steel |

| Control system | Timer control system |

| Weight | 300kg |

| Dimension | 1450*740*960mm |

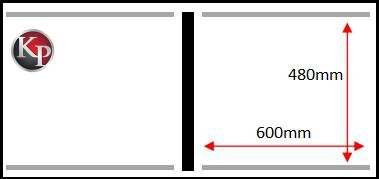

Chamber size picture

Machine Feartures

- Ergonomic full 304 stainless steel swing-lid container with an easy-swing feature.

- Made of full 304 stainless steel structure. very strong and sturdy.

- Four compact stainless steel roller wheels. All of the wheels lock for greater stability.

- Machine chamber height is able to be customized by your request to packing different sizes of the product.

- Time or PLC control system and all machine waterproof.

- Operation user-friendly.

Operation user-friendly

- PLC control system is able to choose.

- Import Germany BUSCH R5RA 0040F vacuum pump.

- Vacuum pack machine work height is able to customized by your request.

- Nitrogen gas flushing function system choice.

- Vacuum pump dust filter system

Shrink Pack Machine function

- Water temperature is able to control easily.

- We also use state-of-the-art heating elements and temperature sensors that allow our water heaters to generate better heat.

Vacuum Pack function

- Extend the shelf life of your product

- Keep your food fresher.

- Saving your money and time

- Be more efficient by optimizing storage, portion control, and transport.

Machine application

The machine is able to pack various types of products food or non-food. If packing fresh meat, it can pack food, chicken, duck, vegetable, fruit, durian, coffee, tea, and so on. If packing non-food, hardware, medical instruments, medicine, pillow, etc.

Sample pack pictures