What is skin technology?

Skin packaging applies vacuum technologies to seal foods in plastic. It’s like a second skin for your product. This process extends the shelf life as well. The package is easy to open, even with one hand, so it’s perfect for you too.

Skin packaging is a great way for your company to present their products. It’s great for sealing, keeping your product in one piece, upholding high safety standards, and preventing the growth of bacteria.

Enjoy the freshness of your food. Once the package is opened, the product is exposed to oxygen and will only take a few minutes to return to its natural color. The taste and freshness will not be altered.

Standard skin packaging

Products are packaged in trays that do not exceed the height of the product.

To get the best skin performance, the tray height should be about 25-30 mm.

Protrusion skin packaging

The height of the product is too tall for the depth of the container in which it is packaged.

To provide the best way for your skin to function, the tray height should be 20 mm or below.

The product can be an additional 30mm to 50mm high above the tray cavity (optional on some machines).

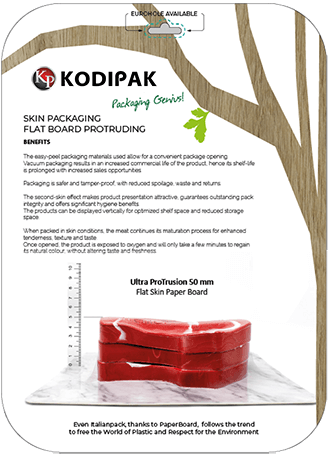

Protrusion on flat support

A new-age evolution of the protrusion packaging. It uses a flat product to put the product in instead of the traditional package.

The product can protrude above the support by a standard 30 mm or 50 mm (optional on some machines).

This packaging method is available on all of the machines in our extensive range and is an excellent choice for those who want to reduce their plastic use. It’s also a good way to make your products look more professional. You can choose from a wide array of printing options for your products, giving them a personal touch.

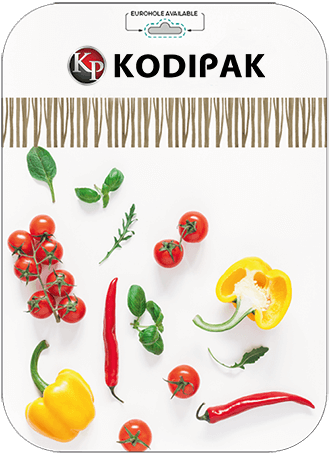

Examples of trays

Trays layout

Front with Eurohole available

Back